iC-Haus iC-MU200

Magnetic Off-Axis Absolute Position Encoder – Pole Width 2.00 mm

- iC-MU200 QFN48-7×7 AEC-Q100 qualified (Grade 1)

- Integrated Hall sensors for two-track scanning

- Hall sensors optimized for 2.00 mm pole width (master track)

Description

iC-Haus iC-MU200

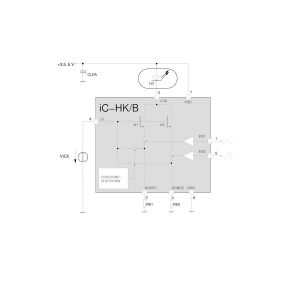

iC-Haus iC-MU200 is used for magnetic off-axis position detection with integrated Hall sensors. By scanning two separate channels i.e. the master and nonius track, the device can provide an absolute position within one mechanical revolution. Position data can be transmitted serially (SSI, BiSS, SPI), incrementally, or analog through two ports in various modes of operation. Commutation signals (U/V/W) for brushless DC (BLDC) motors with up to 16 pole pairs are derived from the absolute position.

Types and Packages

- iC-MU200 QFN48-7×7, RoHS compliant MSL 3, 260°C

Features

- iC-MU200 QFN48-7×7 AEC-Q100 qualified (Grade 1)

- Integrated Hall sensors for two-track scanning

- Hall sensors optimized for 2.00 mm pole width (master track)

- Signal conditioning for offset, amplitude, and phase

- Sine/digital real-time conversion with 12-bit resolution (14-bit filtered)

- 16, 32, or 64 pole pairs per measurement distance

- 2-track nonius absolute value calculation up to 18, 19 or 20 bits for 16, 32 or 64 master pole pairs

- Enlargement of measurement distance with second iC-MU200

- Synchronization of external multiturn systems

- Configuration from an external EEPROM using a multimaster I2C interface

- Microcontroller-compatible serial interface (SPI, BiSS, SSI)

- Incremental quadrature signals with an index (A/B/Z)

- FlexCount®: scalable resolution from 1 up to 65536 CPR

- Commutation signals for motors from 1 up to 16 pole pairs (U/V/W)

Application

- Rotative absolute encoders

- Linear absolute scales

- Singleturn and multiturn encoders

- Motor feedback encoders

- BLDC motor commutation

- Hollow shaft encoder

- Multi-axis measurement systems